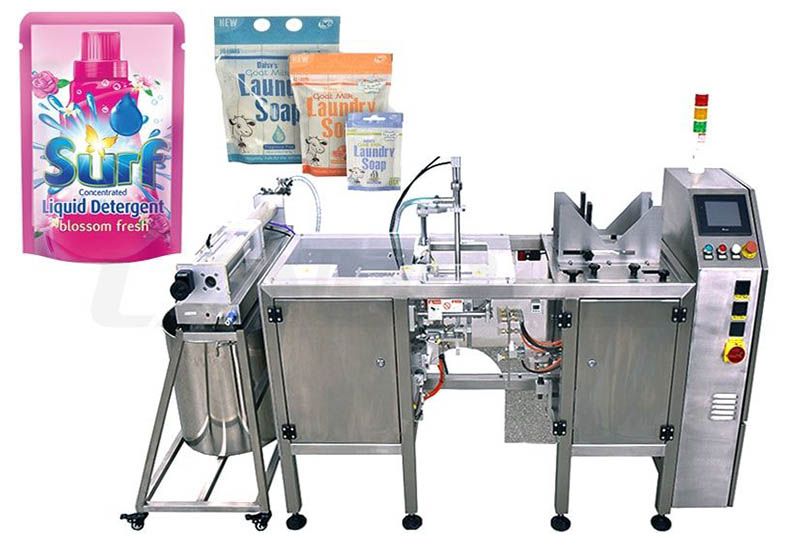

| Optional Devices | 1.Lateral feed device, 2.Straight feed device, 3.Belt material conveyor,4.End sealing auxiliary conveyor, 5.Auxiliary material feeding device, 6.Materia cut prevent device,7.Perforating device, 8.Angle folding device, 9.Date Printer, 10.Labelling machine | 1.Lateral feed device, 2.Straight feed device, 3.Belt material conveyor,4.End sealing auxiliary conveyor, 5.Auxiliary material feeding device, 6.Materia cut prevent device,7.Perforating device, 8.Angle folding device, 9.Date Printer, 10.Labelling machine | 1.Lateral feed device, 2.Straight feed device, 3.Belt material conveyor,4.End sealing auxiliary conveyor, 5.Auxiliary material feeding device, 6.Materia cut prevent device,7.Perforating device, 8.Angle folding device, 9.Date Printer, 10.Labelling machine | 1.Lateral feed device, 2.Straight feed device, 3.Belt material conveyor,4.End sealing auxiliary conveyor, 5.Auxiliary material feeding device, 6.Materia cut prevent device,7.Perforating device, 8.Angle folding device, 9.Date Printer, 10.Labelling machine | 1.Lateral feed device, 2.Straight feed device, 3.Belt material conveyor,4.End sealing auxiliary conveyor, 5.Auxiliary material feeding device, 6.Materia cut prevent device,7.Perforating device, 8.Angle folding device, 9.Date Printer, 10.Labelling machine |