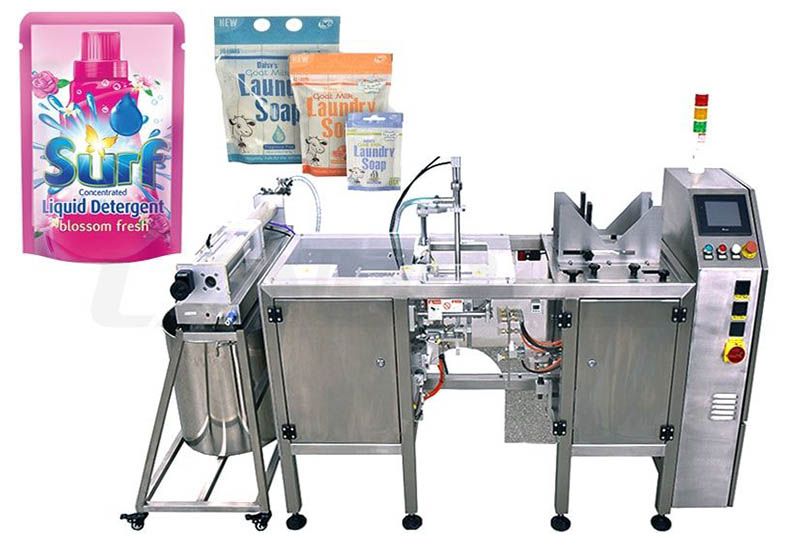

Features:

With menu storage and memory function, the controller can save a variety of parameter configurations, and the recipe can be used when the product or packaging film is changed.

The industry-leading electronic cam algorithm, the bag length range is 60mm---infinite length, the bag length is set and cut, one step is in place, saving time and film.

Advanced electronic anti-cutting, electronic anti-aircraft bag algorithm. The empty material film stops, saving packaging materials.

The horizontal seal is controlled by an independent servo motor, and the longitudinal seal and the feeding tailstock are controlled by a frequency conversion motor.

The mechanical structure is simple, has stable operation, and has low noise.

Automatically track the feeding speed, and the packaging machine will automatically increase and decrease the speed.

Man-machine interface, convenient and quick parameter setting, automatic tracking of color code, automatic correction of cutting length.

Digitally input the sealing and cutting position to make the sealing and cutting position more accurate.

Automatic fault diagnosis, the fault display is clear at a glance.

Well-known brand servo motor/controller/touch screen, vertical sealing/discharging belt brush.