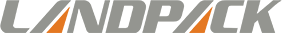

Application

Application:

Mini weighs Auger Filler+Mini Doypack Machine Packing Line Units included easy-dismantle screw conveyor, auger filler, gantry, mini doypack machine and output conveyor, etc;

This is a new popular packing line for the powder in the market, which can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc;

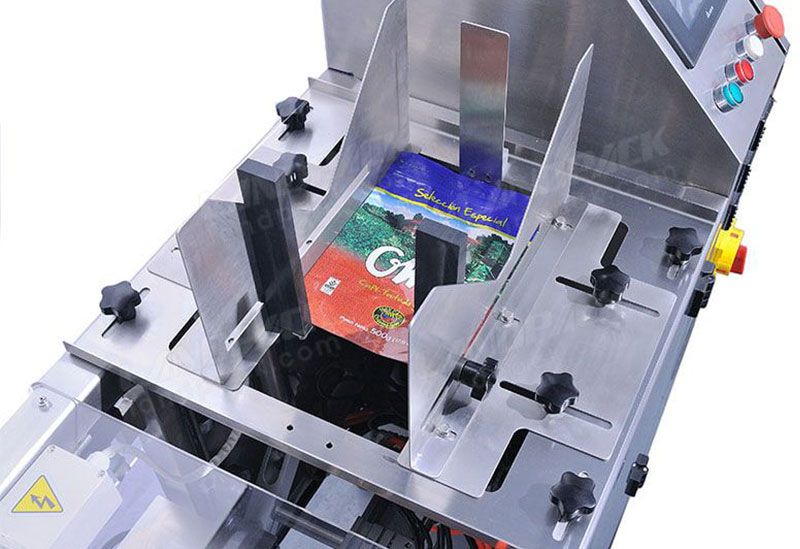

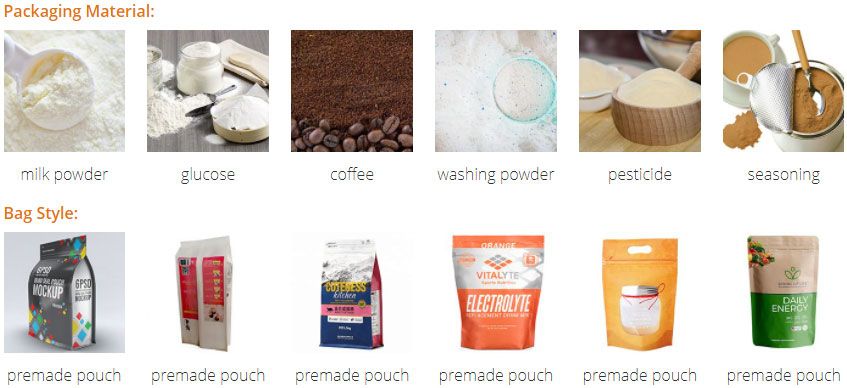

Premade pouch can be 3-side-seal, gusseted pouch, standup pouch with zipper or no-zip-lock. An ideal choice for milk powder, glucose, seasoning, washing powder, chemical materials, pesticides, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Features:

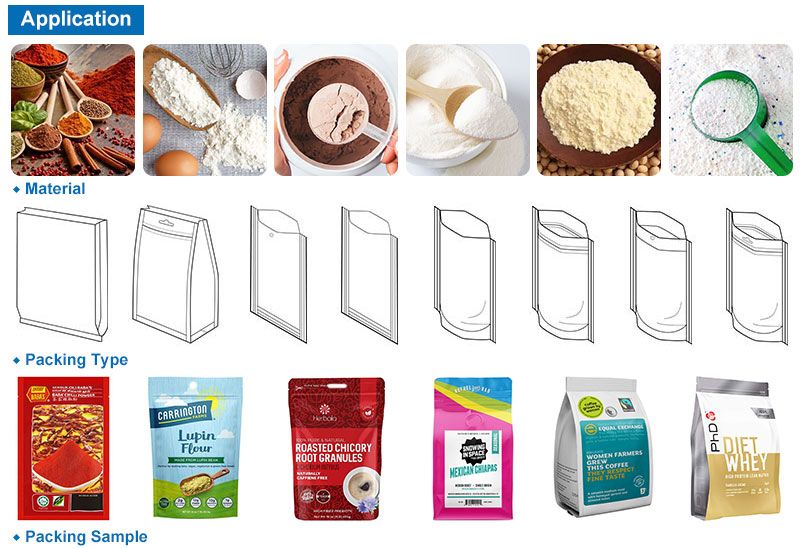

Machine is specially developed for all kinds of composite pre-made bags.

PLC & HMI Control, easy for parameter setting and troubleshooting.

Different pouch size adaption, simple adjustment without tools.

Intelligent temperature controlling configuration, ensure artistic and neat sealing.

Pouch saving design, no completely opened pouch, no filling and sealing

Compatible programs of powder, granule or liquid closing, easy for different products switching.

Machine stopped when the door is opened.

Specifications:

Model: LD-300D/LD--430D

Bag Material: Multilayer Composite Premade Bag (e.g.: PET/PE)

Bag Type: 3 Side Seal Bag, Stand-up Bag

Upgradable Bag Type: Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device)

Size Range: W 80-300mm, L 100-400mm

Speed: 0~15bags/min

Sealing Type: Straight grain, the pitch is 1mm (Optional reticulate)

Sealing Width: 10mm (5-20mm can be customized)

Voltage: 220V, Single-phase, 50/60HZ, 1.2KW

Air Pressure: 0.65Mpa

Air Consumption: 0.3m³/min (Standard machine, no additional function)

Body Dimension: 1770*600*1260mm

Packing Dimension: 1860*710*1650mm (Export non-fumigation wooden case)

Optional Devices:

Pouch zipper opening function.

Gusset pouch opening function.

Gas flush functions to keep the products fresh and avoid them broken.

Air/Nitrogen Inflating, Air deflating function.

Vacuum function to keep the products fresh and reduce the package space.

The bag tapper vibrating compacting function help products drop to the bag bottom part and enhance packaging density.

Grip seal to avoid powders coming out during filling.

Dedusting device to enable a clean packaging environment and ensure the quality of sealing.

Different types of code printing functions, such as hot stamp ribbon printers, inkjet printers, thermal transfer printers and so on.