Features:

Basic Configurations:

Touch Screen: China Kinco 7 inches corlor touch screen;

Languages: Chinese, English, Spanish, Dutch, Italian, Korean (At most three languages);

PLC: Japan Panasonic;

Cylinder: Taiwai Airtac (Can be upgraded to Japan SMC);

Vacuum Generator: China Airbest (Can be upgraded to Vacuum Pump);

Vacuum Component: Japan SMC;

Modular Control System For Vacuum Pressure: Japan SMC;

Modular Control System For Temperature: China YUDIAN;

Electrical Component: Schneider / Omron;

Safety Key Interlock Switch;

The main structure of the machine is SUS304 (The thickness of the rack is 3.0mm), and the material of the part is aluminum;

The part (Hopper) in contact with the material is SUS304 (Can be upgraded to SUS316L).

Basic Functions:

The machine stops running when the safety key interlock switch is pulled out;

No bag prompting function;

Self-diagnosis function of open the bag failed (The bag can be reused); In that case, the machine will not fill and seal, it will re-take the bag;

Positioning (anti-dropping) function of hopper;

Warning function of cartridge heater fault ;

Warning function of cylinder fault.

Warning function which air pressure is not up to standard.

Specifications:

Model: LG1-300L

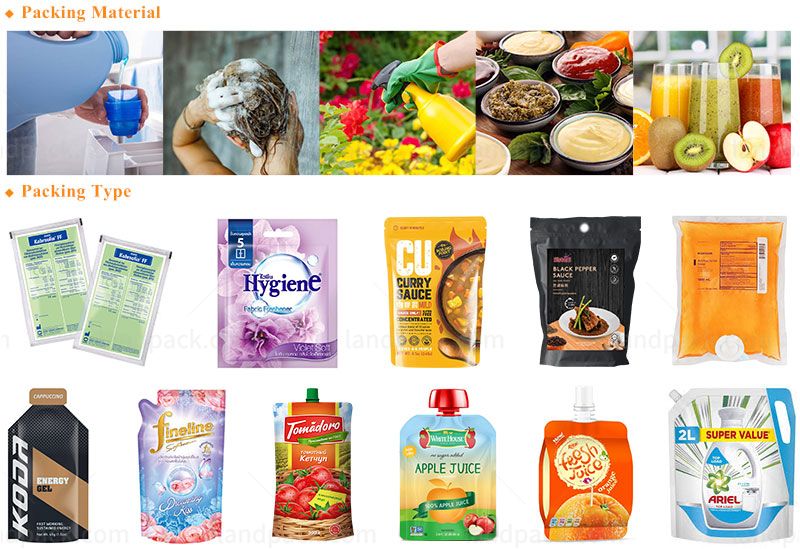

Bag Material: Multilayer Composite Premade Bag(e.g.: PET/PE)

Bag Type: 3 Side Seal Bag, Stand-up Bag

Upgradable Bag Type: Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device)

Size Range: 80mm≤W≤300mm 100mm≤L≤400mm

Speed: 1~15bags/min

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate)

Sealing Width: 10mm (5--20mm can be customized)

Voltage: 220V, Single-phase, 50/60HZ, 1.2KW

Air Pressure: 0.65Mpa

Air Consumption: 0.3m³/min (Standard machine, no additional function)

Packing Dimension: 1860*710*1650mm (Export non-fumigation wooden case)