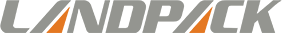

Application

Application:

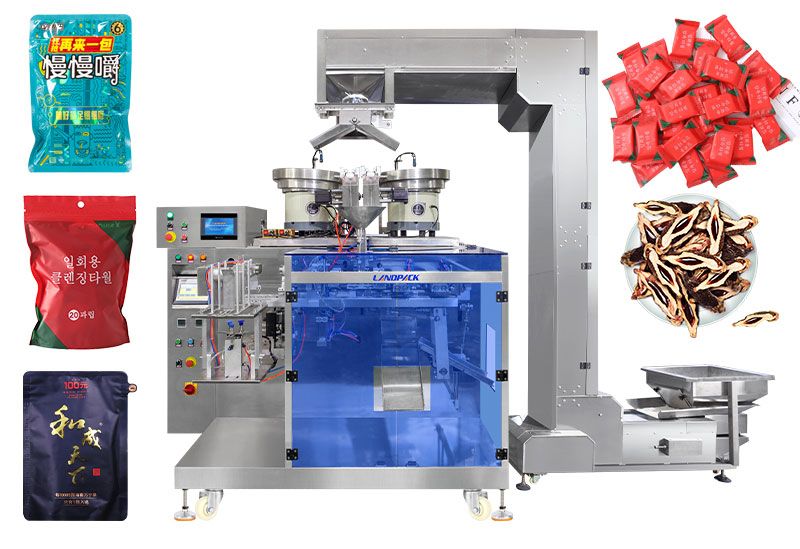

Automatic fine granules horizontal doypack machine with linear weigher, it is suitable for the measurement and packaging of various fine particle products, such as sugar, salt, chicken essence, monosodium glutamate, buckwheat, snacks, etc. after replacing the metering device, it is suitable for packaging liquid and powder products.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Features:

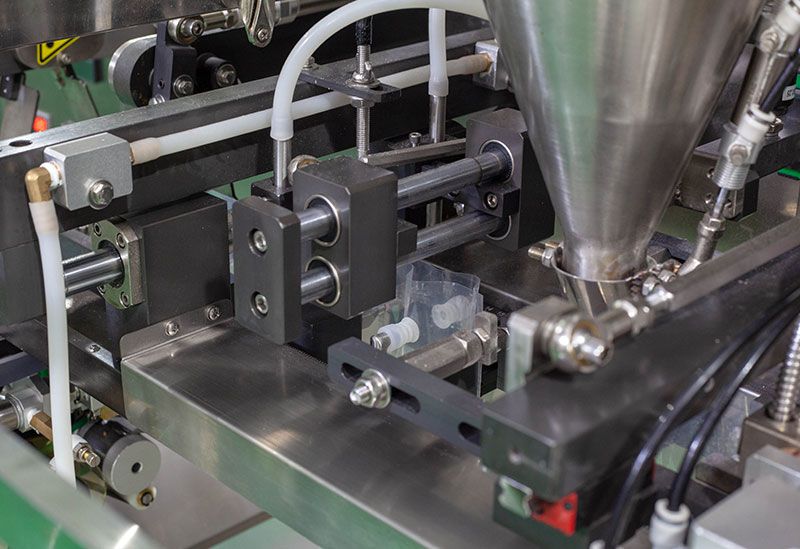

The metering and packaging system consists of a horizontal bag-feeding packaging machine, an linear weigher blanking system, an electronic scale working platform and a Z-type material hoist.

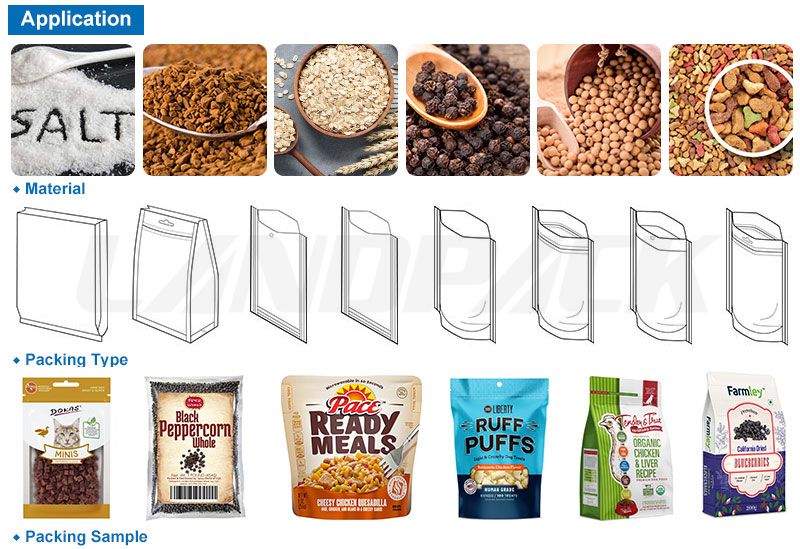

The bag placing slot is convenient and simple to place the bag, equipped with an automatic bag pressing device.

Equipped with imported pressure sensing device to achieve the effect of no blanking and no sealing, saving packaging bags.

Adopting color touch screen, simple operation and multifunctional design.

The machine adopts the appearance of stainless 304L, and the carbon steel frame part and some accessories are processed with acid-resistant, salt-resistant and anticorrosive treatment layer.

Material selection requirements: Most of the accessories are formed by mold production, and the main materials are 304 stainless steel and alumina.

Various coding, coding, exhaust, and punching systems are optional.

Specifications:

| Model | LDSP-160A |

| Pouch Size (mm) | min90*90; max160*230 |

| Packing Capacity | 30-50 Bags/min |

| Power | 3N/380V |

| Machine Size | 1750*1280*1360 |

| Machine Weight | 800kg |

| Packing capacity | 20g-500g |

| Air consumption | 0.7m³/min |

| Packing bag types | various premade pouch such as four-side sealing bags, handbags, paper bags, etc. |

Optional Devices:

Inkjet Printer

Thermal Printer

Exhaust Air

Punching

Temperature Controller

Vacuum Bag Opening Device