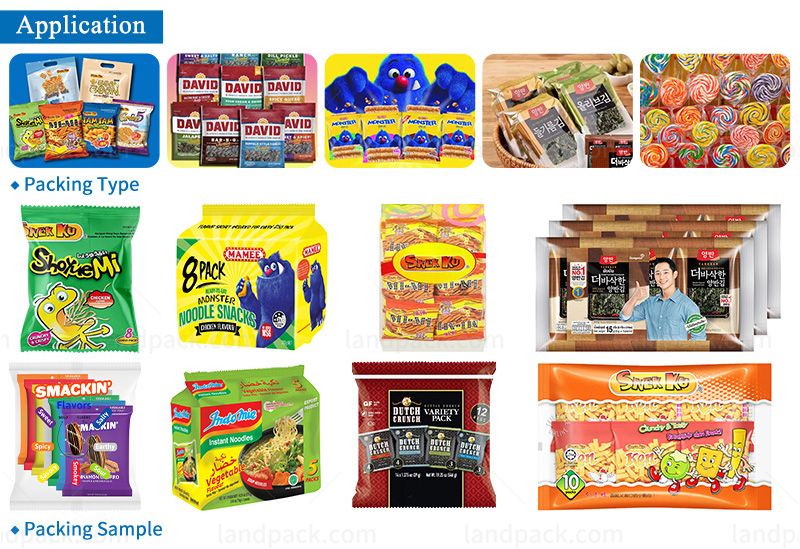

Application

Application :

Boost efficiency with our Automatic Secondary Packing Flow Wrapping Machine—ideal for secondary packaging of snacks, potato chips, instant noodles, bread, and wafers. Features PLC control, SS304 food-grade contacts, pneumatic cutting blades, adjustable bag former, and sponge air-exhaust device to save packing space.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers :

Features:

1. The machine features an industrial-grade PLC with a full-color touchscreen HMI for intuitive operation, recipe recall, and error-free control.

2. All material-contact parts are constructed with SS 304 stainless steel and FDA-approved PU belts, ensuring hygiene and easy cleaning.

3. An end-of-line conveyor with ball-transfer rollers gently supports finished bags and ensures smooth transfer to downstream equipment.

4. The adjustable bag former allows quick width changes in minutes without tools, accommodating various bag sizes.

5. High-precision pneumatic sealing and cutting blades deliver clean, stable cuts even on tall or bulky products.

6. An integrated sponge air-exhaust system removes excess air before sealing, creating compact bags and saving storage/shipping space.

7. The "No-Product, No-Feed, No-Cut" logic prevents film feed and blade action when no items are detected, reducing waste and jams.

8. The multi-language interface supports up to 12 languages for global use without software modifications.

9. It accommodates jumbo roll films up to 1000 mm wide, enabling high-throughput production.

10. A servo-driven film feeding system ensures precise, stable film advancement and consistent bag lengths at varying line speeds.

Specifications:

| Model | LP-1000X |

| Film width | Max.1000mm |

| Bag length | 240-700mm |

| Bag width | 150-430mm |

| Product height | Max.150mm |

| Packaging rate | 20-40 bags/min |

| Power | 220V, 50/60Hz, 6.5kw |

| Machine size | 4300*1270*1550mm (L*W*H) |

| Machine quality | About 850kg |

| Frame Material | Carbon steel as standard. SS304/316 are optional |

| Film material | OPP/ PE/ PVC/ OPP/ CPP/ PT/ PE/ KOP/ CPP/ Aluminum Coating Film/ Aluminum Film |

Optional Devices:

Date Coder

Automatic Punching Device

Auto labeling device

Nitrogen generator