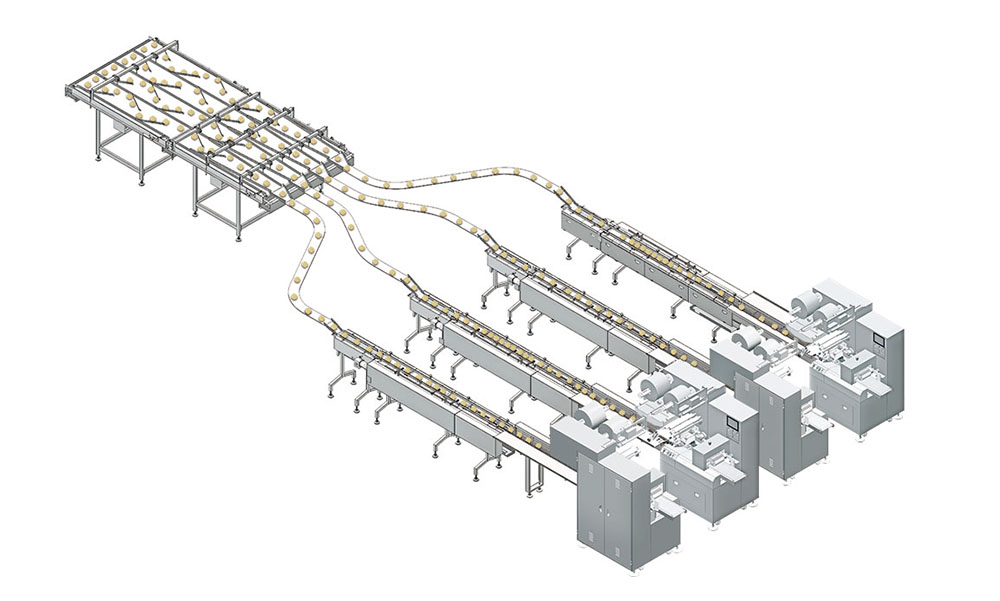

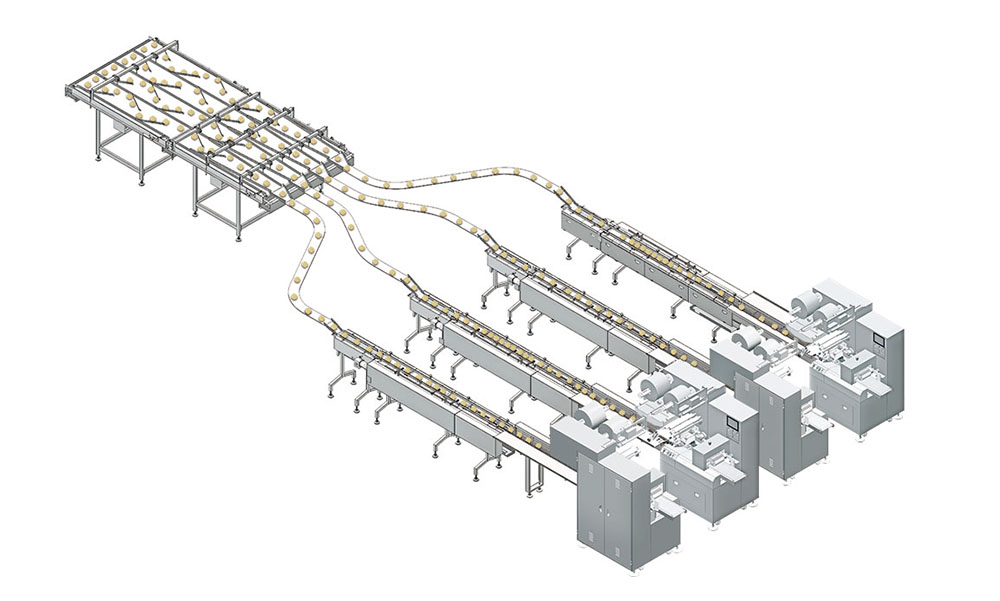

Automatic Instant Noodles Clear-Up Line

This machine line can directly connect the finished product delivery belt of the front -end processing line, meet the scale of single items, mass production packaging requirements. It can also use manual dumping materials to meet the small batches of multiple varieties of specifications, multi -batch production of multi -batch production Packaging requirements.

This machine line can be personalized according to the characteristics of the material to avoid squeezing deformation to the material. In the case of material congestion, stacking, and unsuccessful steering, it can be automatically eliminated without stopping to ensure the continuity and stability of the production packaging.

This product adopts multi -level variable frequency speed adjustment, servo driver control, simple operation, convenient, stable operation, high control accuracy, low energy consumption.

This product adopts stainless steel and aluminum alloy structure, which is humanized design, installation, disassembly, maintenance, simple and fast.

This product enables boring transportation, collation, arrangement, supplies, and packaging to achieve fully automation.

Thissequipped with a cross-row system with cross-type automatic transportation to meet the entire automatic transportation and sorting of the opponent, round, and strip products to avoid artificial operations.

It can be designed according to the characteristics of the product to avoid squeezing deformation of the material.

In the case of material congestion, stacking, and unsuccessful steering, it can be automatically eliminated without stopping to ensure the connection and stability of the production packaging.

It adopts multi-level frequency conversion speed regulation and servo-driven control. It can use the user's requirements for packaging speed and material shape characteristics to use 4 to eight-level adjustment and control. It has strong adaptability.

It adopts humanized design, simple and fast installation and disassembly.

It is equipped with multiple safety measures, including leakage protection, emergency stop function, fault stop protection, protective cover (opening the cover), warning lights, etc.

The Application Range:

Full auto high speed transportation, arrangement, feeding and packing for all kinds of wafer, chocolate, cake and solid regular object which length 80-150mm, width60-80mm, and height15-20mm.

The main functon characteristics:

1.Adopt multistage variable speed control, servo drives control, easy operation, stable running, high degree of control preciseness,low energy consumption.

2.Adopt colored touch screen, easy operation adn adjustment, fault display, data storage function, to operate easy for changing different size products.

3.High sensitivity and preciseness SICK photocell tracking system,to control product pisition exactly.

4.Adopt full stainless steel structure, Humanized design,and easy install disassemble , and maintenance.

Parameters:

Model

| LP-WH2

|

Capacity

| 30-200 packs/ min |

Packing Film Width (mm)

| 90-370mm

|

Packing Size

| L80-150,W60-80,H15-20MM |

| Total Power (kw) | 5.0kw |

| Power Supply | 220V50Hz |

| Net Weight | 600kg |

| Outer Dimension (l*w*h) | 5000*1500*1600mm |